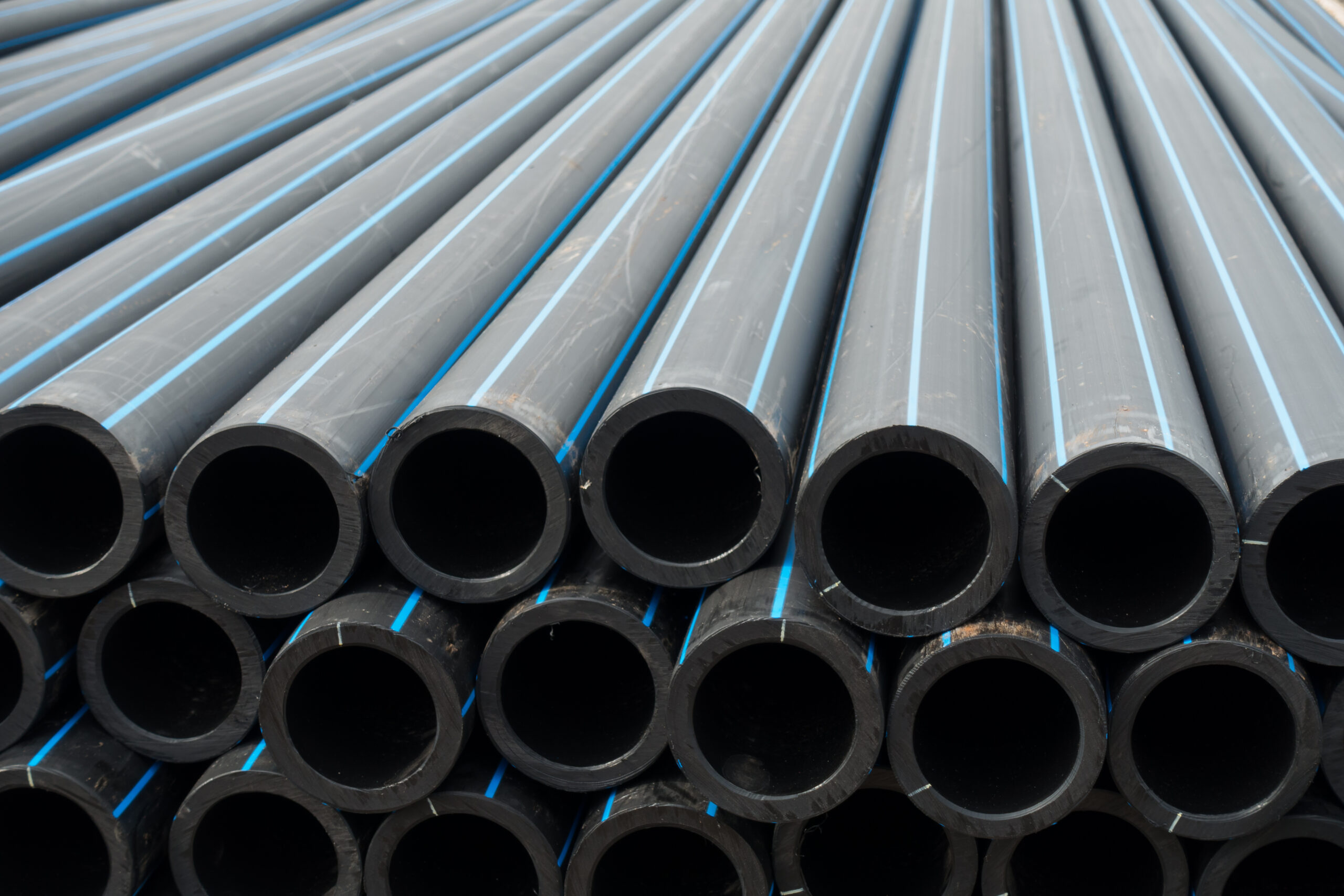

Polyethylene (PE) and Polyvinyl Chloride (PVC) pipes and fittings are two of the most widely used materials in plumbing, irrigation, and various industrial applications. These versatile materials offer durability, corrosion resistance, and ease of installation, making them essential components in modern infrastructure systems.

Polyethylene (PE) Pipes and Fittings:

- Composition: Polyethylene is a thermoplastic polymer derived from ethylene gas. PE pipes and fittings are manufactured through a high-pressure extrusion process, resulting in lightweight yet robust products.

- Applications: PE pipes are commonly used in potable water supply, irrigation, sewerage systems, and gas distribution networks. They are also employed in industrial applications such as chemical processing and mining.

- Advantages: PE pipes exhibit excellent resistance to corrosion, chemicals, and abrasion, making them suitable for harsh environments. They are flexible, allow for easy installation, and have a long service life with minimal maintenance requirements.

- Types: PE pipes come in various types, including High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE), each offering distinct properties suited to specific applications.

Comparison and Considerations:

- Cost: PVC pipes are generally more cost-effective than PE pipes, especially for smaller-diameter applications.

- Temperature Resistance: PE pipes have a higher temperature resistance compared to PVC pipes, making them suitable for hot water and industrial applications.

- Installation: Both PE and PVC pipes are lightweight and easy to install, but PE pipes offer greater flexibility, especially in colder climates where PVC may become brittle.

- Environmental Impact: PVC pipes may contain additives such as phthalates and lead, raising concerns about environmental and health implications. PE pipes are considered more environmentally friendly and recyclable.

Conclusion: Polyethylene and PVC pipes and fittings play integral roles in modern plumbing, irrigation, and industrial systems, offering durability, versatility, and ease of installation. Understanding the properties, applications, and considerations of these materials is essential for selecting the most suitable solutions for diverse infrastructure needs.

At DCM we work based on the category of products. If you are interested in any category and would like to discuss ordering, please contact DCM experts. We have capable specialists who can calculate the scale of your project and estimate your requirements to provide you with premium tailor-made solutions at competitive prices.

Reviews

There are no reviews yet.