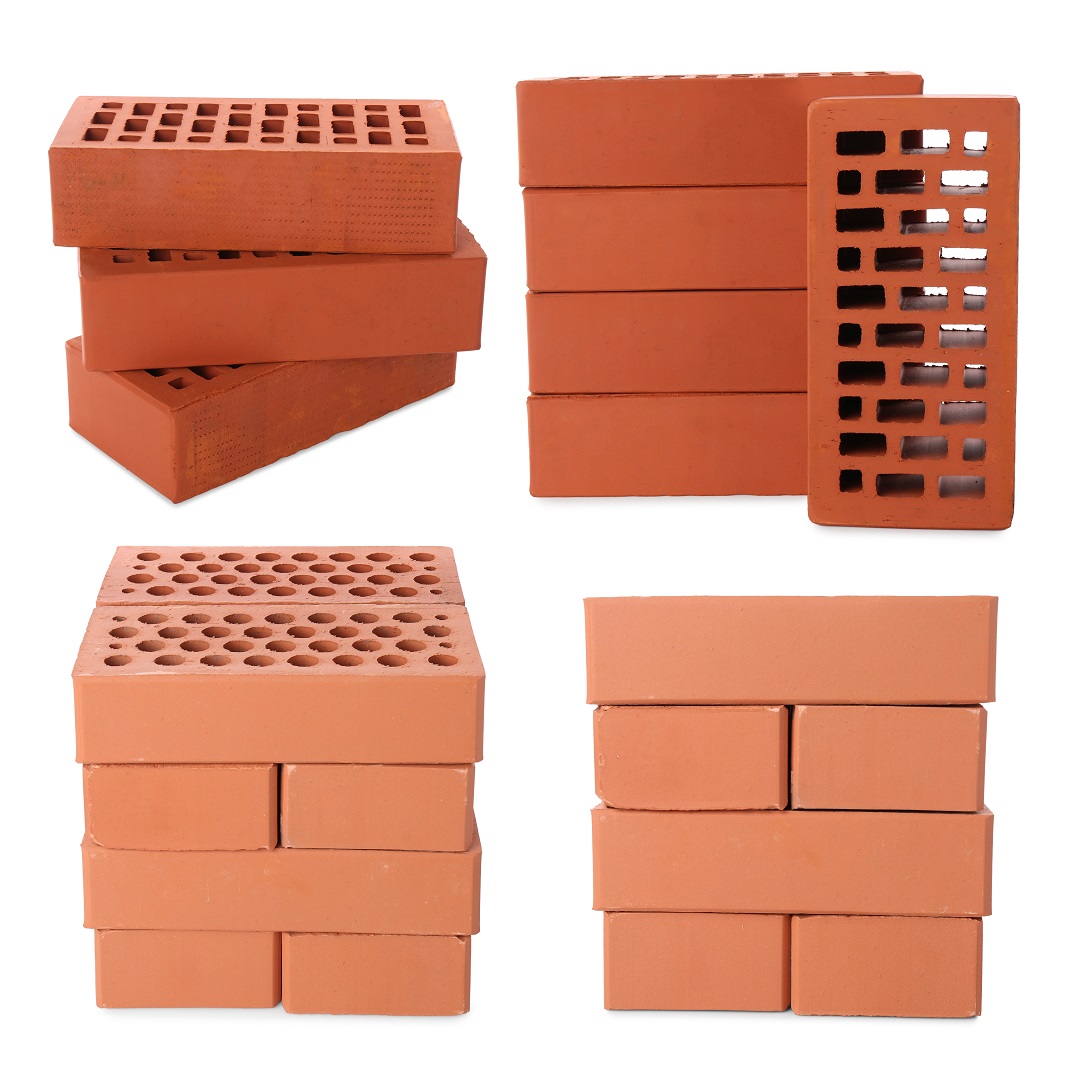

Bricks are rectangular blocks made from clay or shale and used primarily in construction for building walls, pavements, and other structures.

Manufacturing Process:

- Preparation: Clay or shale is mined and prepared.

- Molding: The material is shaped into bricks through pressing or extrusion.

- Drying: Bricks are dried to remove excess moisture.

- Firing: Bricks are fired in a kiln at high temperatures to achieve hardness and durability.

- Cooling: The fired bricks are gradually cooled before packaging.

Advantages:

– Durability: Long-lasting and resistant to weathering and fire.

– Strength: Provides structural stability.

– Thermal Mass: Helps in maintaining indoor temperature.

– Aesthetic Appeal: Offers a timeless look.

Applications:

– Building Construction: Walls, foundations, and structural components.

– Paving: Pathways, patios, and driveways.

– Landscaping: Garden walls and retaining walls.

– Fireplaces: Construction of hearths and chimneys.

Environmental Impact:

– Natural Materials: Made from abundant natural resources.

– Longevity: Long lifespan reduces the need for frequent replacements.

– Energy-Intensive: The manufacturing process requires significant energy.

Challenges:

– Weight: Heavy, making transportation and handling challenging.

– Cost: Can be more expensive than other materials.

– Environmental Impact: The production process contributes to carbon emissions.

At DCM we work based on the category of products. If you are interested in any category and would like to discuss ordering, please contact DCM experts. We have capable specialists who can calculate the scale of your project and estimate your requirements to provide you with premium tailor-made solutions at competitive prices.

Reviews

There are no reviews yet.